X Teeth Wet and Dry Using Diamond Saw Blade for Super Thin Cutting Tile Granite Marble Ceramics

Basic Info

| Model NO. | N/A |

| Blade Type | X Teeth |

| Manufacturing Process | Sintered |

| Application | Tile Granite Marble Ceramics |

| Model | X-Teeth |

| Advange | Super Thin Seg |

| Machine | Angle Grinder, Circular Saw |

| Use | Wet and Dry |

| Transport Package | Skin Card/Colour Box/Double Blister/Master Carton |

| Specification | 4′′-7′′ |

| Trademark | SINO ABRASIVES or OEM |

| Origin | China |

| HS Code | 82023900 |

| Production Capacity | 500000PCS/Year |

Packaging & Delivery

Package size per unit product 10.00cm * 10.00cm * 10.00cm Gross weight per unit product 0.500kgProduct Description

SUPER THIN

The tile cutter blade's outer edge is plenty strong, X teeth super thin turbo mesh rim diamond blade provides fast, precise, smooth, and chip-free cutting.

MULTI-PURPOSE

Wet and Dry cutting, for cutting porcelain, ceramic tile, granite, sandstone quartz, marble, brick, and cement backer board.

LONG LIFE

A high-Performance diamond matrix will provide long life and enhanced material removal.

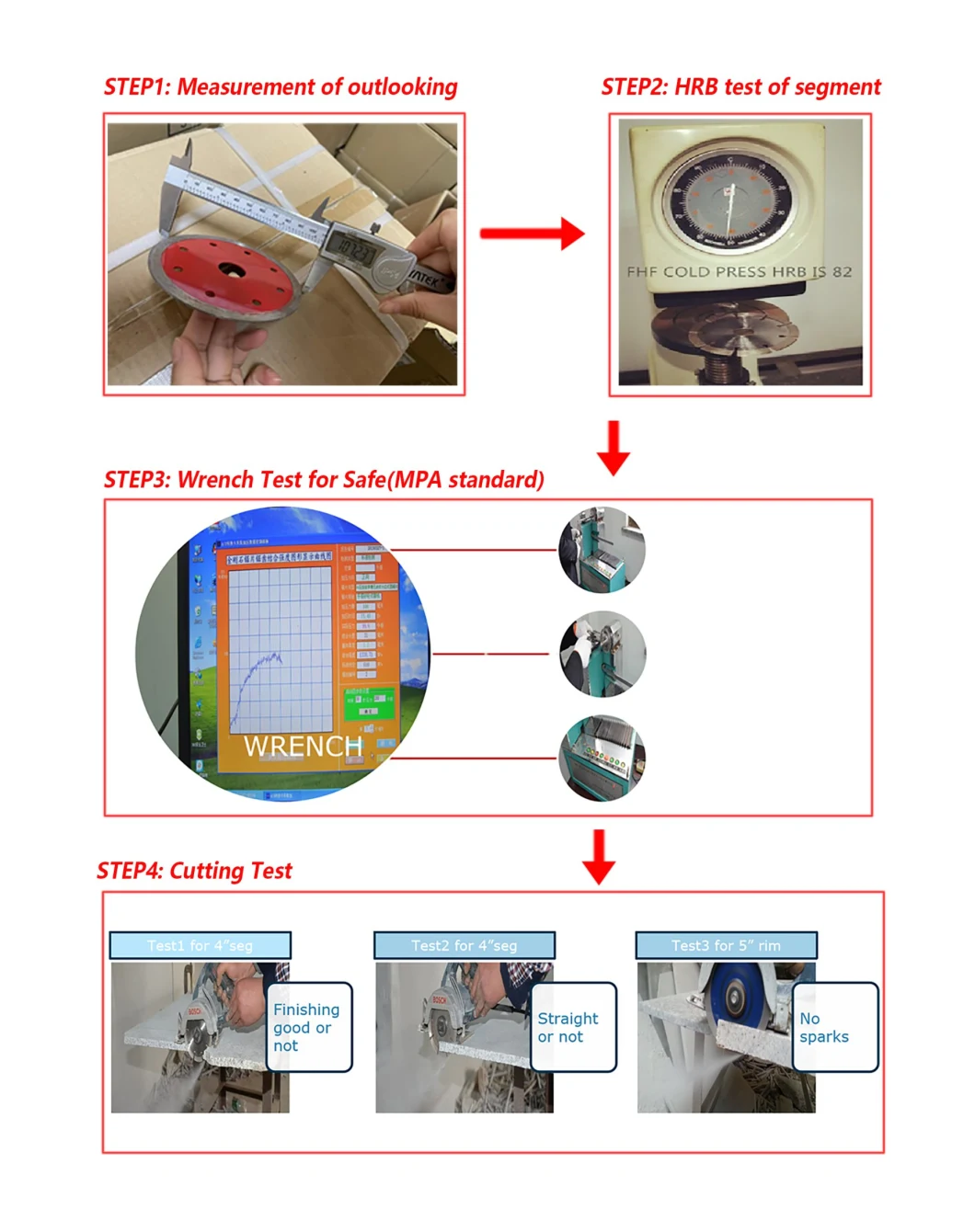

| Test of Supervision |

| Related Products |

| Packing&Shipping |

| Company Profile |

Sino abrasives designs develop, integrate, and manufactures a complete range of cutting, grinding, and polishing products for all kinds of customers. Including, Superhard materials- Diamond tools, CBN tools, T.C.T tools, Resin bonds abrasives, Sanding tools, Non-woven tools, and so on.Sino Abrasives Limited was born in 2003. It's initially just an abrasives tools factory. After a decade of hard work, we had been an integrity manufacturer and owned the full automatic abrasives production line, Superhard materials production line, and Laser welded line.We are always focused exclusively on the Creative and Service. We sincerely hope can supply the most appropriate service and products to you!

WHY CHOSE US?

1-Raw material cost advantages:

Sino abrasives limited cooperated with the best partners including international suppliers and domestic suppliers:3M, NCA BUFFALO, CUMI, SINOMACH, ZHONG NAN, ZZSM, and so on.

Our production center covers an area of 14000 square meters. Full automatic machines are more than 70%. The abrasives' capacity is more than 0.9 million pieces per month.Besides, automatic machines can produce more precisely and more standardly. Benefiting from it, we can easily keep the quality stable.

| Our Customers |

| Certifications |

| FAQ |

1. Are you a manufacturer?

A: Yes, we have our own factory, and have excellent research team, and strict quality inspection procedures. We will surely don'thave a middleman. Also, welcome you visit our factory.2. What about your quality?

A: We have strict quality inspection procedures, and each of our new products has been tested before launching it in the market.3. Can you provide samples?

A: Yes, we can provide samples for you, yet the express fee need to be paid by you.4. If you don't have the size I need, can I have a requirement?

A: Yes, if the size you need we don't have, we can manufacture it as per your requirement. It will have a minimum order.