YZFM-800SA China Supplier BOPP Thermal Film Paper Lamination Machine

Basic Info

| Model NO. | YZFM-800SA |

| Membrane Material | Thermal Film (BOPP. Pet.etc) |

| Plastic Film Mulching Modes | Hot Laminating |

| Performance | Waterproof |

| Max. Sheet Size | 800*1040mm |

| Min.Sheet Size | 250*250mm |

| Paper Thickness | 105-500g/Sq.M |

| Production Speed | 40-80m/Min |

| Total Power | 25kw |

| Transport Package | Wooden Case+Pallet |

| Specification | 7200*1800*1900mm |

| Trademark | Huawei |

| Origin | Ruian Zhejiang |

Product Description

Brief introduction:

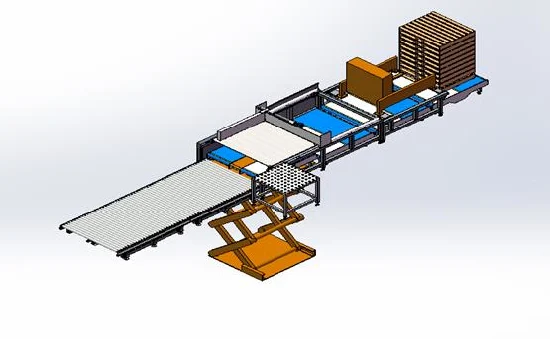

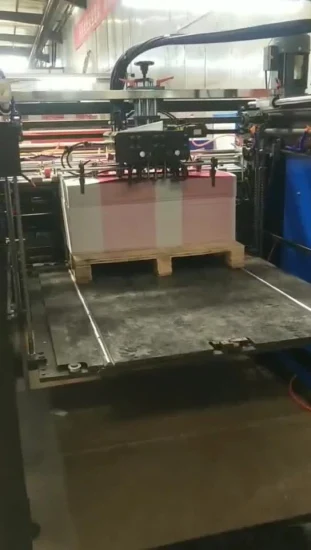

YZFM-800SA, Automatic thermal film Laminating Machine is controlled by Delta PLC. One person operates easily. This Highly automated equipment can shorten the time of procedure and enhance efficiency. The diameter of main heating pressing steel roller is 370mm. and this steel roller is heated by heat transfer oil, circularly heated by the mold temperature machine.

This laminating machine is equipped with film separating and punching devices. With sheet drawing control installed (Pull gauge).Machine features:

•High speed feeder

China's best brand Feeder, with double sheets detector

•Laminating unit

The diameter of main pressing steel roller is 370mm. This machine is equipped with film separating and punching devices. Paper overlap adopts servo technology, precision is high.

•sheets Separating unit

The laminated products passed the punching devices were separated easily. There are pressing roller and pulling roller to separate sheets.

Separating unit adopts pneumatic device, it is automatic, operated easily

| Model | YZFM-800SA |

| Max. Sheet Size | Width 800 × Length 1040 mm |

| Min. Sheet Size | 250×250mm |

| Suitable Paper Thickness | 105-500 g/m2 |

| Suitable Film Supply | BOPP Thermal Film only |

| Max. Production Speed | 70 m/min |

| Laminating Temperature | Approx. 85-125ºC |

| Total Power | 18.07kW |

| Overall Dimensions | 6900×2400×1900mm |

| Total Weight | 2800kg |

Our highly skilled engineers take pride in producing top of the line machinery that is world renowned for its quality, reliability, and productivity. Highly active in R&D, Shanghai Tiancen Machinery Manufacture continually expands into new technologies and applications including:

Film Laminating Machines Ink Jet Spot UV / 3D Spot UV & Foiling Ink Jet digital printer for code/Bar code/ QR code Roller Coat UV varnish coater Playing card cut, collate machine

We manufacture in Shanghai, China, an area recognized as the China's science and technology, trade, information, finance and shipping centers. Our machinery is built by skilled engineers. We utilize top quality components. This quality in manufacturing allows our customers to produce higher quality print with a greater perceived value. Our machinery is designed to with very little down time or regular maintenance requirements, saving our customers invaluable time and financial resources.We manufacture machinery with exceptional productivity, which often reduce labor costs and provide a very quick return on investment.