Single Facer Corrugated Cardboard Making Machine 2-Layer Corrugated Board Production Line Corrugating Paper Production Line

Basic Info

| Model NO. | KD-CPL |

| Paper Thickness | Normal Specification Paper |

| Design Speed | 120m/Min |

| Steam Consumption | 2000kg/Hour |

| Total Power | Around 100kw |

| Dimension(L*W*H) | 75m*15m*6m |

| Max Paper Width | 1400mm-1800mm |

| Max. Width of Corrugating Roll | 1470mm-1870mm |

| Working. Pressure | 1.0-1.3MPa |

| Transport Package | Wrapped in PE Film or Cotton Cloth, Then Packed by |

| Specification | Depends on paper size |

| Trademark | KADING |

| Origin | Dongguang, Cangzhou, Hebei |

| HS Code | 84393000 |

| Production Capacity | 100sets/Year |

Product Description

Product Description

Single Facer Corrugated Cardboard Making Machine 2-Layer Corrugated Board Production Line Corrugating Paper Production Line

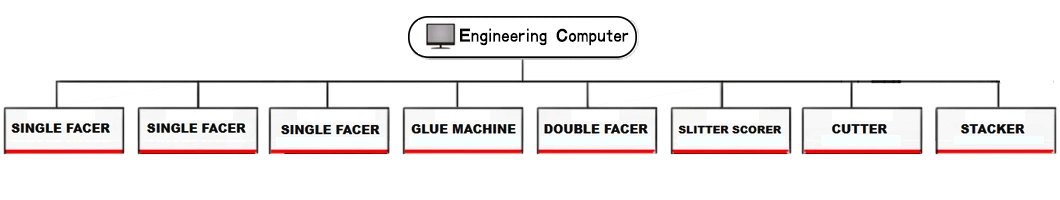

Corrugated cardboard production line is the professional equipment for producing corrugated cardboard .The production line consists of the Mill Roll Stand, liner(medium paper ) Pre-heater, Single facer machine ,Conveyor bridge , Gluing Machine, Double facer machine , Slitter Scorer , Cut-off , Conveyer and Stacker, Heating System ,Air compression system and Glue Making System and so on.We produced different grade 3,5,7 ply corrugated production line with different fitting. On the base of understanding the requirements of the customers and the advanced skills at home and abroad, our company has developed and designed these production lines with the speed 60~220m/min, the paper with 1600~2200mm and A,B,C,E UV flute production line can satisfy different customers.Product Parameters

No. | Name | Details |

1 | Mill roll stand | Electric mill roll stand , expansion dop top, pneumatioc brake |

2 | Single facer | vac-sorb,φ320 alloy roller ,cardan drive |

3 | Feeding paper bridge | Electric adjust deviation,adsorb tension |

4 | Second gluing machine | Conversion synchronous control |

5 | Triply pre-heater | φ 800,electric wrap angle (including qualification certificate ) |

6 | Pre-heater | φ 800,land type electric wrap angle (including qualification certificate ) |

7 | Dry formed part | 520mm×18 pieces hot plate ,adopt Adopt up and down intensive roller(including qualification certificate ) |

8 | Heat formed part | Adopt up and down intensive roller ,length 8m |

9 | Feeding paper belt | High quality carton belt , electric promote |

10 | Thin blade slitter scorer machine | 5 blade 8 line , electric Correct error , alloy blade |

11 | Corss cutter | Computer control cutting cardboard length 500-9999mm; cutting cardboard precision ±1mm |

12 | Main drive | Main power 25KW |

13 | Make paste system | Barrel type ,electric stir circulate glue design |

14 | Stand feeding paper car | Include slipping way |

15 | Pump | Electric aeration |

16 | Electric system | One Operate cabinet ,one sinlge facer 1 main drive |

17 | Steam system | Not including heat source and pipe |

18 | Gantry stacker | Belt drive type |

Cangzhou Kading Carton Machinery Manufacturing was founded in 2004 and is located in Dongguang County, Cangzhou City, Hebei Province. We are a manufacturing enterprise that produces carton making machinery.Our company's self-produced product lines include carton printing machines, carton die-cutting machines, and carton slotting machines; our advantageous products include Carton stitching machines, Folder gluer machines, Flute laminating machines, Single facer machines, etc. After nearly twenty years of sales and production experience, our product supply chain is already very mature, so we can help customers one-stop purchasing.In addition to our own foreign trade business, our factory also cooperates with many trading companies, so our products are exported to dozens of countries such as the Middle East, Africa, Southeast Asia, and the European Union, and are well received by the majority. There are also many brand&branded manufacturers among our customers. You are welcome to cooperate with us~!

Q: Are you a factory or a trading company?

A: We are a direct manufacturer that is located in Dongguang county, Cangzhou city. Welcome to visit our factory! We can also have video call if you'd like an online factory tour

Q: How do you ensure your quality?

A: 1. Trustworthy and long-term cooperative raw material suppliers;2. Skilled&experienced engineer&workers;3. Mature QC system;4. Specially-assigned merchandiser;5. Advanced production workshop

Q: How about your after-sale service?

A: 1. Special after-sale team will be 24/7 online;2. Can guide the installation door-to-door;3. One-year warranty for spare parts.