High Speed Servo Semi-Auto Flute Paperboard Laminating Machine

Basic Info

| Model NO. | 8500 |

| Certification | ISO9001 |

| Application | Machinery & Hardware |

| Driven Type | Electric |

| After-Sales Service Provided | Overseas Service Center Available |

| Type | Automatic Carton Making Machine |

| Automatic Grade | Automatic |

| Name | High Speed Servo Semi-Auto Flute Paperboard Lamina |

| Keyword | High Speed Servo Semi-Auto Flute Paperboard Lamina |

| Finish Product | Corrugated Box |

| Voltage | 380V |

| Power | 8kw |

| Speed | 0-100PCS/Min |

| Max Feeding Size | 1300*1600mm |

| Max Laminating Width | 1600mm |

| Weight | 3000kg |

| Precision | 1 mm |

| Transport Package | Waterproof Plastic, Wooden Case, Iron Frame |

| Specification | 8500*2200*1800(mm) |

| Trademark | Canghai |

| Origin | Hebei |

| HS Code | 8441809000 |

| Production Capacity | 1 Set/60days |

Product Description

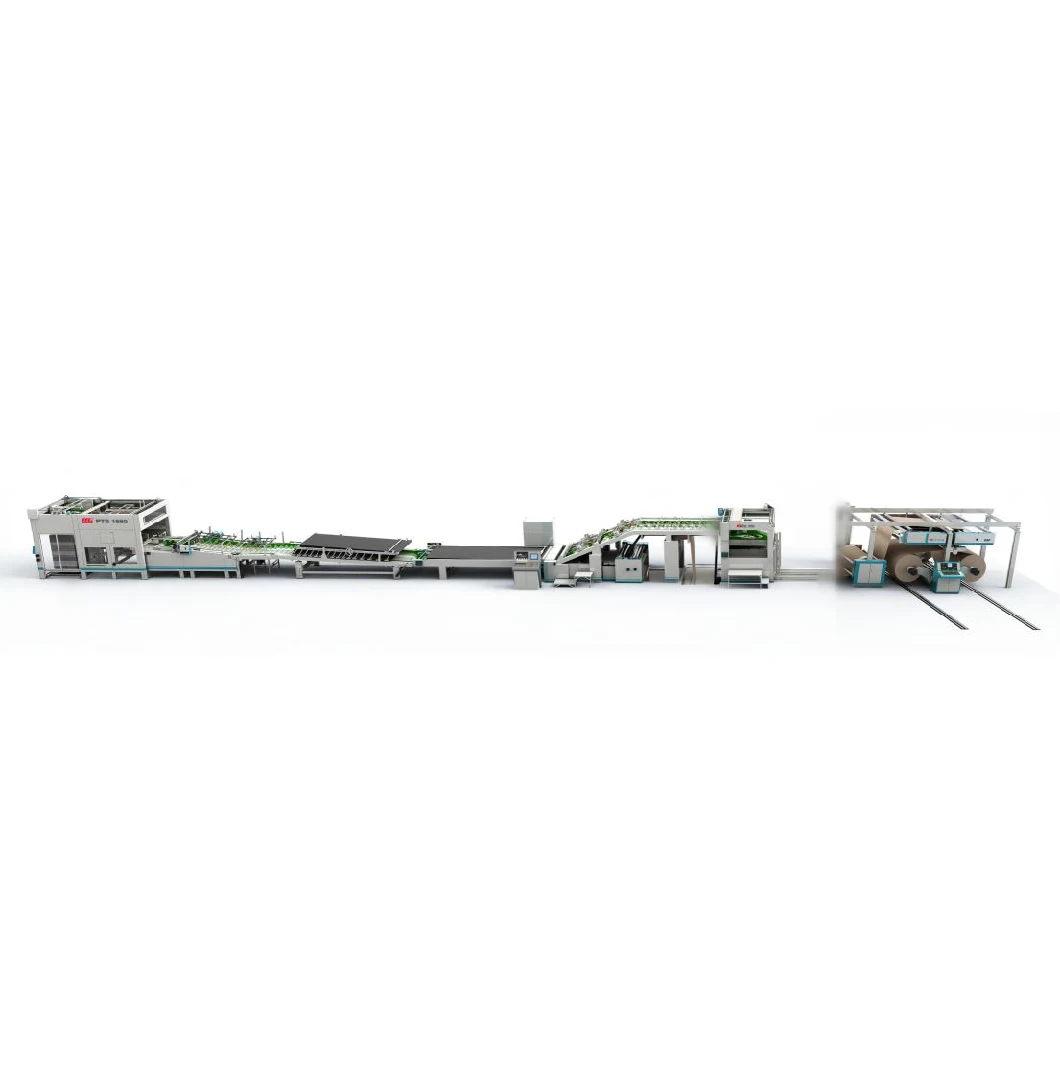

high speed servo semi-auto flute paperboard laminating machine

Flute laminating machine. it is general by feeding mechanism, pasting paper agencies, institutions and pressure feed mechanism is two layers of institutions, pasting mechanism is two layers of institutions, whose character is on the feeding mechanism of the upper body and set up two, in the middle of the pasting institutions set up with positioning, pasting institutions can be divided into two way paper, set in the two sides of the pasting institutions winged leaf spring, intermediate positioning mechanism is composed of intermediate positioning guide block and lifting mechanism, intermediate positioning guide block connected to the lifting mechanism.

Complete Machine Specification

Model | CH-1300 | CH-1500 | CH-1600 |

Max.size | 1300mmX1300mm | 1500mmX1300mm | 1600mmX1300mm |

Min. size | 360mmX360mm | 360mmX360mm | 360mmX360mm |

Economic speed | 0-100 pcs/min | 0-100 pcs/min | 0-100 pcs/min |

Precision | ±1 | ±1 | ±1 |

Power | 8.5kw | 8.5kw | 8.5kw |

Outter size | 8.8m x 1.95m x 1.7m | 8.8m x 2.15m x 1.7m | 8.8m x 2.25m x 1.7m |

Weight | About 3T | About 3.5T | About 3.5T |

Feature

- independent research and development, is the domestic semi-automatic high-speed servo machine initiative enterprises.

- The whole machine adopts PLC control system, which is more accurate and stable than other delay device or intermediate relay control, and greatly improves the speed. Circuit fault can automatically display alarm.

- Delta servo motor from Taiwan is adopted to eliminate signal conversion control of brake, clutch and low-light eye;PLC, servo single control independent operation, fast speed, high precision, easy to operate.

- The base paper adopts suction automatic paper feeding, which can be automatically and synchronously tracked according to the speed and continuity of the surface paper, and automatically and continuously paper feeding.

- Pre-specified position of new concept, high positioning accuracy, and the backing paper will never lead;The advance amount of face paper can be adjusted;

- Automatic glue supplementation system, which can automatically supplement the amount of glue lost in the bonding process, and cooperate with glue recycling to avoid glue loss and waste;

- Scientific design of the linear speed of the measuring roller to ensure uniform glue loading and avoid glue rejection during high-speed operation;

- Rubber roller cleaning is adopted to make the lower roller clean and complete, and the back of corrugated paper is not viscose, saving the trouble of changing scraper frequently;

- Floating movable press can ensure that the corrugated paper will not be compressed after mounting, and at the same time ensure that the cardboard is flat and straight;

- Independent water tank is used to control the water circulation to clean the water source, which is not easy to accumulate glue;

- Single side adjustment of roller pressure. When changing the specification of the base paper, only one side can roll to the required scale

Finished Carton box made by High speed flexo printing machine for carton box

Applicable industry

Clothing factory, shoe factory, food factory, pharmaceutical factory, pesticide packaging, beverage packaging box, handicraft packaging, cup packaging, electrical packaging, battery car packaging, children's toys packaging, logistics packaging, furniture packaging, all kinds of small commodity packaging, industrial small parts packaging.

Company Information

Packaging & Shipping

1)Inside packaging could be iron frame:it is more firm to avoid shake and damage.

2)Outside packaging could be wooden case: the wooden case is of soft texture could reduce damage from impact

3)Waterproof plastic: keep goods dry and avoid damp

4)We also accept customized regarding the package

Trade Shows

Customer visit

For now, we have client from South east Asia and south Asia, Middle east, Europe, American, Africa and so on place. They buy not only flexo printing slotting die cutting machine for sale but also other product we supplied. In addition, we could help customer to order other product we dont production.Customers are welcome to visit our factory and most of them satisfied with our product quality, factory scale as well as our service. If you are interesting, please dont hesitate to come meet us!

Certificate

Our Services1)Three years warranty for machine. technical to door service.

2)English manual and Video for machine using and maintenance.

3)We offer free training in our factory, welcome to visit and learn more about our machines.

4)Free accessories: Software ,manual, book, videos, USB control

FAQ1. Are you a trading company or factory?

We are the manufacturer and also we have import export license.

2. Where is your company located? How can I visit there?

Our factory address: dongguang county, Cangzhou city, hebei province,China

3. Can you send technician for installation and training?

Yes, we can send our technician abroad for installation and training, but all the charges must be paid by buyer, such as the plane tickets (a round trip), meals, hotel, traffic etc.

4. Whats your warranty time

We can take 3 years warranty, actually our longest cooperation customer have been using our product for more than 10 years with no problem.