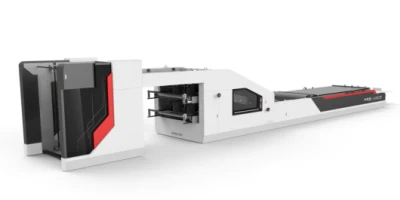

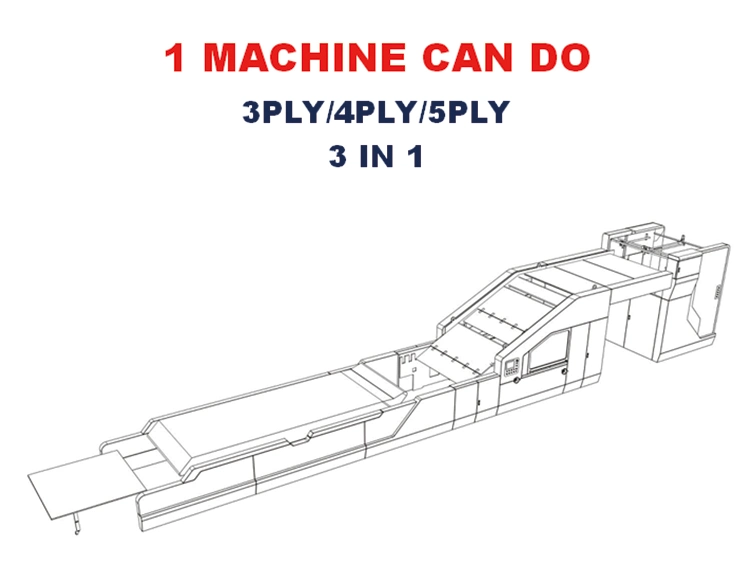

Fully Automatic 5 Ply Multi Function Film Flute Laminator Machine Paperboard Laminating Machine

Basic Info

| Model NO. | 450F |

| Plastic Film Mulching Modes | Cold Laminating |

| Performance | Waterproof |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Name | Laminating Machine |

| Laminating Type | Autoamtic |

| Max. Paper Size | 1580X1100mm |

| Min. Paper Size | 500X500mm |

| Bottom Paper | a/B/C/E/F/G 2ply Flute |

| Face Paper Thickness | 150-600GSM |

| Max Speed | 6000PCS/H |

| Height of Face Paper Pile | 1600mm |

| Precision | ±1.5mm |

| Transport Package | Plastic Film and Wooden Box |

| Specification | 1300/1450/1600F |

| Trademark | XINGLONG |

| Origin | China |

| HS Code | 8443139000 |

| Production Capacity | 200 Per Year |

Product Description

Fully Automatic 5 Ply Multi Function Film Flute Laminator Machine Paperboard Laminating Machine

Introduction:

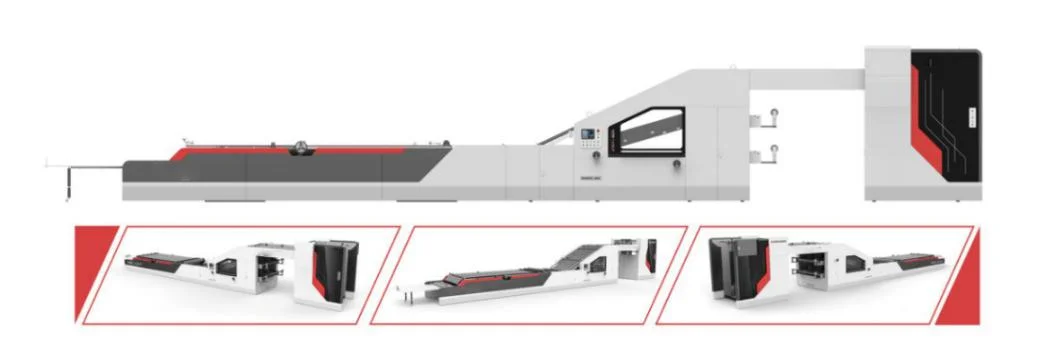

The fully automatic multi layer flute laminator is consists of automatic face paper lifting section, face paper conveying section, double bottom paper synchronized or asynchronized conveying section, double bottom paper positioning section, cyclic gluing section, pressing section, delivering section and automatic collecting section. It suits to laminate the printed paper to the corrugated board or cardboard which is thicker than 350gsm, with features of high precision and high speed. It is the ideal laminating machine for all kinds of packaging company domestic and overseas.

Machine structure:

1. Face paper conveying section adopts advanced four sucking and four delivering feeder, with the help of high pressure vacuum pump it can feed the face paper 180-600gsm efficiently. Position displaying hand wheel on the face paper pile loading section makes the loading action more accurate and more convenient for the bottom paper loading at the same time. Limited switch fixed on face paper loading section makes the moving up action more accurate.

2. Conveying belt, pressing roller and automatic chasing lay all do help to the face paper delivery. Pressing roller adopts the specialized roller which is used on print machine, it can delivery both thick and thin paper effectively. Anti-curl structure helps to delivery face paper at the same time.

3. Both bottom paper feeding section adopt vacuum sucking belt with high strength and high friction allowing the non-stop feeding. Rotating paper supporter equipped on this section makes it possible to feed the long sheet.

4. Knurled roller on the bottom feeding part makes sure the stable running when the machine in a high speed.

5. Chasing lay and high-speed axial flow fan differential positioning system is applied on the bottom paper feeding part. You can adjust the front and back position without stopping the machine. Synchronous slot design can control the bottom paper feeding in a minimum range; Chasing lay can make sure a good bottom sheet feeding when the machine is running at a high speed.

6. Gluing system has liquid induction device, glue will be supplied accordingly and will be recycled, glue cost will be reduced greatly.

7. The gluing system in this machine is a combination of anilox type steel roller and rubber glue even roller in which the rubber glue even roller is core structure designed and differential speed gluing method is applied to make a even glue and increase the gluing quality. Averagely 25-35grams glue will be used on one square meter, reducing the cost and improving the laminated paper board quality.

8. Both bottom paper and face paper adopt front elastic registration lay so that there is no need to readjust for big or small paper. The intelligent control system makes it possible to adjust the face paper position automatically when the machine is in running. The digital instrument on the front lay part can make the front lay adjustment range to 0.1mm.

9. Photoelectric detector helps the conveying of top or bottom paper accurately..

10.Grooved steel positioning wheel has long service life and easy to clean.

11.Double pre-pressing roller are equipped on the laminating unit.

12.Automatic damping system is applied on the bottom sheet feeding system to prevent the curving of the laminated sheet.

13.Two pressing conveyors with differential speed are equipped on the machine to prevent air bubble and gluing failure problem.

14.Floating type pressing conveyor makes it possible to adjust the pressure according to the paper board thickness. The pressed paper board is solid and strengthen.

15.Automatic collecting device can reduce the labor intensity effectively.

16.All the electrical components are imported; PLC and HMI control system are safe and reliable. Many control knobs are equipped on the machine according to the ergonomics allowing you to control the machine in different position; machine speed is controlled by the frequency converter which makes the machine run stably.

17.Machine is driven by imported timing belt and wheel gear with high efficiency, low noise and stable running status. Low production cost and convenient maintenance

Specification

Model | 1300F | 1450F | 1600F | ||

Max paper size | 1280x1100mm | 1430x1100mm | 1580x1100mm | ||

Min paper size | 500x500mm | ||||

Face paper thickness | 150-600gsm | ||||

Bottom paper | A/B/C/E/F/G 2ply flute | ||||

Precision | 1.5mm | ||||

Max Speed | 6000pcs/h | ||||

Height of face paper pile | 1600mm | ||||

Face paper table capacity | 1500kg | ||||

Height of bottom 2ply pile | 400mm | ||||

Total power | 20kw | ||||

Dimension | 15x2.2x2.6m | 15x2.4x2.6m | 15x2.5x2.6m | ||

Machine weight | 5000kg | 5500kg | 6000kg | ||

Quality assurance and service assurance

1,The product design obeys the user's opinion, constantly improves, and ensures the stability and humanization of the whole machine from the design point of view.

2,The company's quality control department to purchase, processing, assembly of all aspects of quality supervision and management, multi-angle management to ensure the implementation of the company's product quality management.

3,The company quality control department to each finished product in accordance with the factory product standards for inspection.

4,Strong technical strength and efficient after-sales service team guarantee to solve all kinds of problems in the process of customer use, perfect quality information feedback management, make the product improve quickly, and always be in the leading position of technology.

Technically training

Our company sends the professional operation engineer to be responsible for the installation and debugging of the equipment as a whole. During the debugging process, we train the operator for the user in the factory of the customer. The contents are: introduction of the mechanical structure, adjustment of the components of the equipment, etc. The use of electrical operation switches and precautions, equipment daily maintenance and maintenance, in order to ensure the normal operation of the equipment in the future;This product after-sales service is the responsibility of our company in the local nearest service center and the distributor: the company has the strong technical personnel and the after-sales service personnel team, carries on the exchange with the dealer and the user technical personnel regularly, And according to the market situation to the distributor after-sales service personnel training from time to time.

One-year warranty life time maintenance

Since the date of purchase of the machine, our company will provide installation, due to quality causes maintenance and replacement services (vulnerable parts and technical support after acceptance is not in the warranty scope); But human improper operation, non-mechanical quality problems caused by the accident, our company will charge the cost of the main components;One year from the date of purchase, there are some failures in the customer's equipment. Our company will provide paid services to the customer, including technical support, fault maintenance and replacement of the original factory accessories

DONGGUANG XINGLONG PACKAGING MACHINERY CO., LTD. is specialized in the production of various kinds of carton equipments of the well-know enterprise. Factory for over twenty years, we introduced advanced technology at home and abroad, developing and manufacturing products, has been well received by customer. We are specialized in producing 3ply, 5ply, 7ply corrugated cardboard production line, high speed printing machine, ordinary printing machine, single facer, rotary die cutter and other corrugated cardboard production equipment .products are distributed Russia ,the Middle East, Africa, Southeast Asia, EU and other countries and throughout the country. Product quality and enterprise reputation get the high praise at home and abroad. Over the years the company take "the quality first" "integrity-based" corporate purpose always meet user're-equipments as our sole purpose, providing the products with excellent quality, professional technology. Our company is willing to cooperate with domestic and foreign insight, strive for innovation, coexist win-win, hand in hand altogether will create packaging future.

1.

Q: Are you a manufacturer, trading company or a third party?

A: We are a manufacturer, located in Mahai industrial area south of Dongguang county, Hebei province, China. Warmly welcome to visit our company.

2.

Q: What is your minimum order quantity, can you send me samples?

A: Our minimum quantity is 1 set, as our product is machinery equipment, it's difficult to send you samples, if you have any questions about the products, please feel free to contact us for more detail, we are glad to provide you more information such as specifications, video, etc.

3.

Q: How does your factory do regarding quality controlling?

A: 1) All raw material we used are environmental-friendly

2) Skillful workers care every details in handling the producing and packing process

3) Quality control department are specially responsible for quality in each process

We have been kept providing high quality products by introducing advanced technologies for over 20 years, and our products are also widely exported to many different countries including Russia, the Middle East, Africa, Southeast Asia, EU, etc, which earned us a high reputation among the customers.

4.

Q: How about the after-sale service?

A: 1) TM online for 24 hours, also contact by email, skype, MSN, whatsapp, etc.

2) To solve the problems with videos/pictures.

3) One year warranty for spare parts change.