Corrugated Paper Cardboard Board Electric Pallet Forklift Lifting Lift Power Stacker

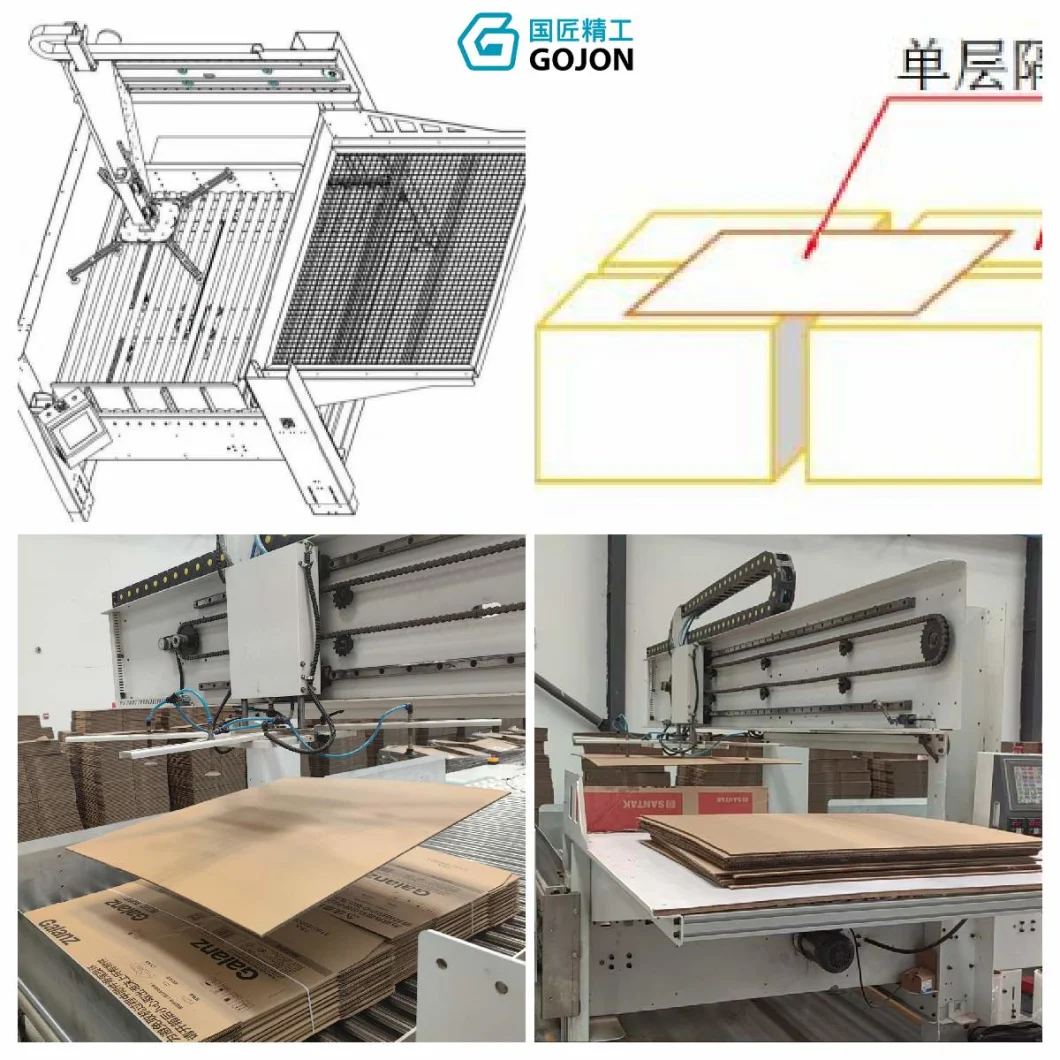

Fully Automatic PalletizerThe automatic palletizer is suitable for the automatic die-cutting machine, automatic box glue;

Basic Info

| Model NO. | gojon-0005 |

| Origin | Qingdao, China |

| HS Code | 84418090 |

| Production Capacity | 100 |

Product Description

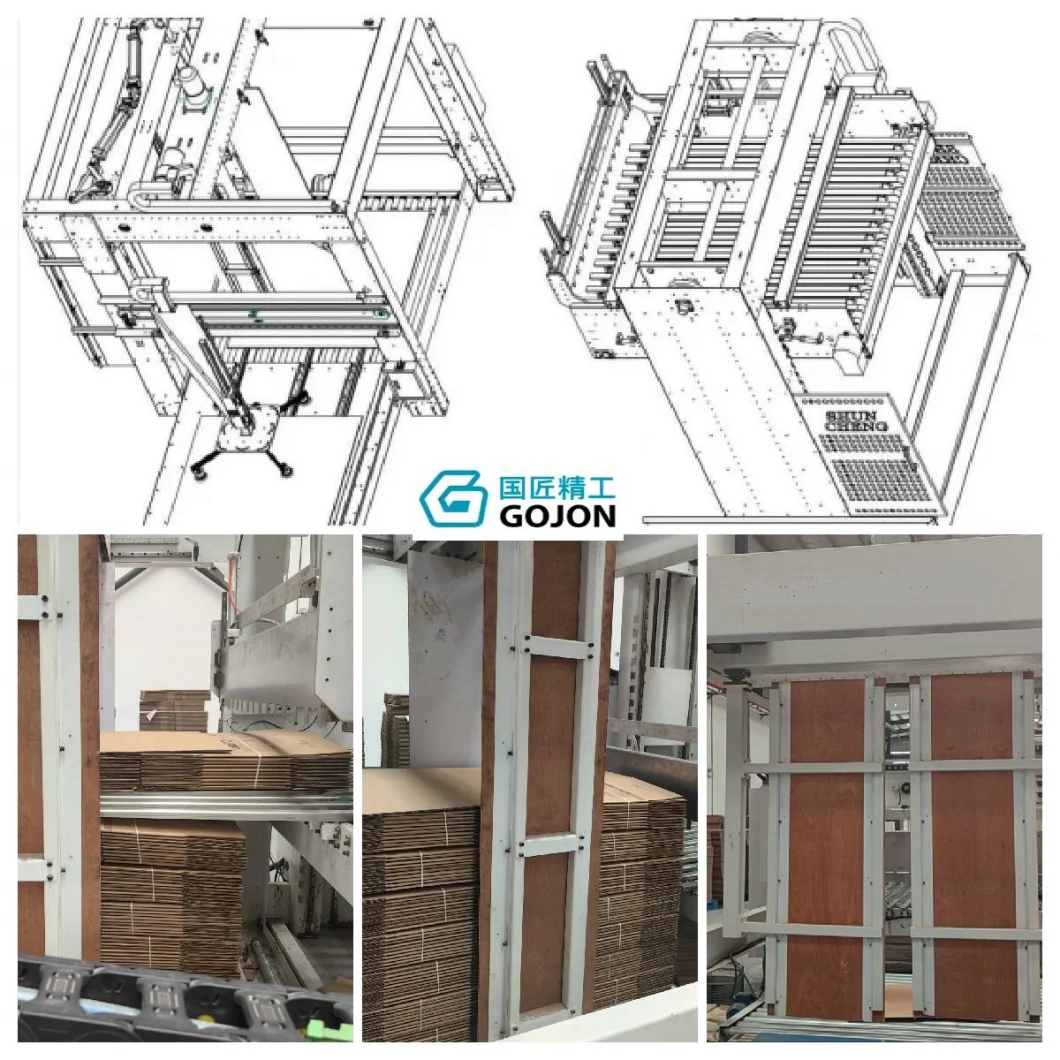

Fully Automatic PalletizerThe automatic palletizer is suitable for the automatic die-cutting machine, automatic box gluer, automatic nailing machine and automatic stacking of the post-process of the linkage line of corrugated cardboard boxes, and can realize the automatic stacking of packed and unpacked boxes. According to the product stacking method requirements, set and switch the corresponding stacking method in the operating system for stacking. There are multiple stacking methods set in the system. It is convenient and quick to change money in one minute, which saves you labor and improves work efficiency. Intelligent linkage.1.Tech parameter:

| Model | SC-1800MD |

| Machine size(L*W*H) | 14290mm*5000mm*3500mm |

Finished product size after stacking | Max:1700mm*1700mm*1800mm |

| Min:800mm*800mm*1800mm | |

| Single bundle product size | Max:1700mm*1700mm*250mm |

| Min:300mm*300mm*50mm | |

| Single layer paper size | Min:1500mm*1500mm |

| Min:600mm*600mm | |

| Pallet size | Max:1500mm*1500mm*150mm |

| Min:1000mm*800mm*150mm | |

| Single layer Max load | 15KG |

| Single pallet Max load | 180KG |

| Lifting stack speed | 4 layers/minute (Note: limit speed) |

| Rotation positioning speed | 10 bundles/minute (Note: the interval between each bundle is more than 6 seconds) |

| Power | 15KW |

| Weight | 9T |

Remarks: The maximum and minimum dimensions of the palletizing product do not include the height of the ground conveyor. The height of the ground conveyor is: 350mm±10 mm, and the speed is: 20m/min. | |

2.Component:1.Interval front and back flip mechanism (optional purchase):

According to the stacking needs, the front and back flip mode is selected by PLC setting (the front and back flips for each stack or stack), and the selected front and back sides are controlled by the divider.

2.Auto Rotator:

According to the demand of palletizing, the direction or angle to be rotated is set in the control system, and the steering mechanism is controlled by the servo motor to complete the rotation work in cycles.

The rotated palletizing products are positioned before and after the palletizing requirements, and then the arrangement is automatically excluded from the single-layer palletizing method, and at the same time, the interlayer can be set to automatically place the separator paper.

4.Single-layer lifting palletizing and pallet palletizing:

Single-layer products after palletized are sent to the lifting palletizing mechanism automatically. After the lifting palletizing mechanism rises to a certain height of the pallet stacking, the single-layer palletizing product is pushed to the pallet to complete the palletizing, and then the pallet is raised to the next layer of stacking height for circular stacking automatically. When the pallet reaches the specified height, the whole stack is automatically output, and at the same time, the pallet is automatically supplied by the automatic pallet feeding mechanism for the next palletizing work.

You may also like

Send inquiry

Send now