Brand New Roll to Roll Flexo Printing Machine 8 Color Price

Basic Info

| Model NO. | YTD-8 |

| Printing Color | 8 Colors |

| Anilox Roller | Ceramic Anilox Roller |

| Dryer | UV& IR |

| Type | Ink Jet |

| Embossing Structure | Rotary Letterpress |

| Structure | Satellite |

| Application | Flexible Packaging Printing |

| Automatic Grade | Automatic |

| Printing Speed | 250m/Min |

| Max.Width of Printing Material | 1200mm |

| Max.Printing Width | 1160mm |

| Length Rang of Printed Products | 300~1000mm |

| Max.Diameter of Material Roll | 1000mm |

| Suitable Ink | Water Based Ink or Solvent Ink |

| Ink Pump | Pneumatic Double-Way Diaphragm Pump |

| Transport Package | Film Packaging |

| Specification | 11*3.6*4.36m(L*W*H) |

| Trademark | LISHG |

| Origin | Zhejiang |

| HS Code | 84431600 |

| Production Capacity | 20sets/Month |

Packaging & Delivery

Package size per unit product 11000.00cm * 3600.00cm * 4360.00cm Gross weight per unit product 8500.000kgProduct Description

Technical parameter (YTD SERIES) | Max Width Of Material | 1200mm |

Max Printing Width | 1160mm | |

Suitable Material | paper , films , non-woven , fabric , foils | |

Printing Color | 8 colors | |

Max Printing Speed | 250m/min | |

Machine Weight | 17000kg | |

Machine Dimension | 11*3.6*4.36m ( L * W * H) | |

Machine Power | 380V,3PH,50HZ |

Main Features1) Central impression type printing machine with better color registration. Due to the big drum, the printed material is supported by the big drum, and greatly improving color registration, especially with extensible materials.

2) All colors printing station drived by the central drum, Less transmission errors because of less gear transmission, increase the registration precision.

3) Adopting high-quality motor, high-quality inverter, save the electricity, reduce the run fluctuation.

4) The machine is equipped with blower and heater; and the heater employed central temperature control system, automatic temperature controller, and separated heat source.

5) The use of individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.

6) Roller adopts special steel processing, and through special treatment, greatly reduce the beating range.

7) Printing roller uses static balance and dynamic balance processing, hard anode oxidation treatment, small resistance, beating small, achieves finally perfect printing effect.

8) Accurate printing effect achieved by special gear transmission device.

9) The printing machine all can choose advance configurations to achieve the high quality, the high-definition effect.

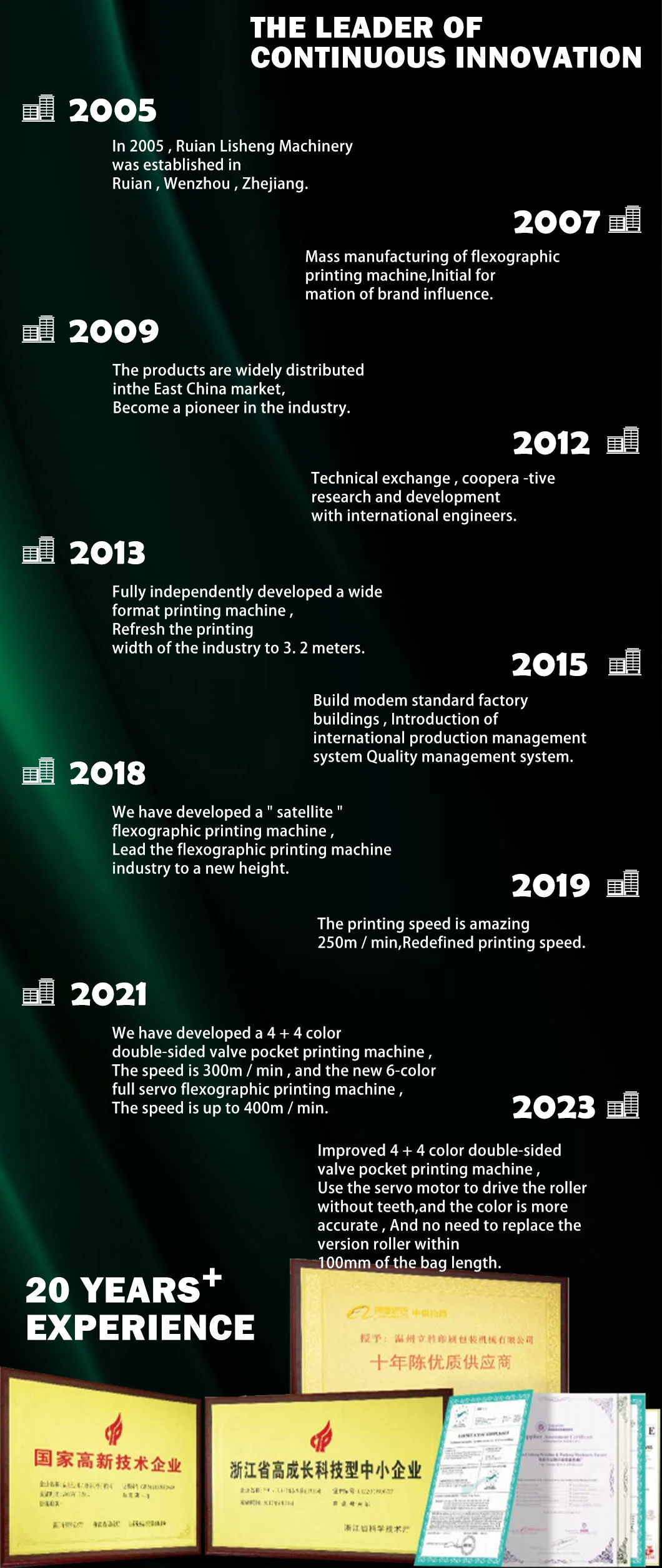

1.Are You a Factory or Trading Company?

We are a factory, with 20 years experience on machines, our products sell very well all over the world.

2.Where is your factory located? How can I visit there?

Our factory is located in Ruian Zhejing China. The nearest airport is Wenzhou airport. It's about 40 minutes by plane from Shanghai (5 hours by train). All our cliens, from home or abroad, are warmly welcomed to visit us.

3.What can the machine print on?

Our machine is multifunction, can do roll to roll printing, such as paper, plastic, woven,nonwoven and so on .

Surely, you can send us your products, and we'll offer you the proper machine.

4.Can I get some samples? How can I get it ?

Yes, we can send you some free sample, but you are reponsable for delivery charages of TNT or DHL.

5.How about the after service?

We can arrange engineers to service overseas.

6.Why choose Lisheng Machinery?

We are one of leaders in this field(in China). Our high-quality products and service enabled us to expand our market from china to more than 60 countries.