Automatic Paper Hot Laminating Machine, Board Paper Laminating Machine, Paper Core Machine

MS-1450 High-speed flute Laminating machine (Servo-driven) Technical Data * THIS CATALG FOR REFERENCE OLY, SPECIFICATION;

Basic Info

| Model NO. | MS-1450 |

| Certification | Ce |

| Transport Package | Wooden Box |

| Specification | 15000X2250X2350 |

| Trademark | Huawei |

| Origin | Wenzhou |

Product Description

MS-1450 High-speed flute Laminating machine (Servo-driven)

Technical Data| Model | DX-1450 | |

| Max. Sheet Size (W*L) | 1450*1450mm | |

| Min. Sheet Size (W*L) | 450*450mm | |

| Thickness | Top sheet | 120~600gsm |

| Thickness | Bottom sheet | 0.5-10mm(B,A,AB,E flute, etc.) |

| Laminating Accuracy | ±1.5mm | |

| Max. Speed | 150 m/min (Subject to board quality and specification)e.g. around 10,000 sheets/hour at length 600mm | |

| Power | 22kw | |

| Dimension L*W*H | 15000x2250x2350mm | |

| Height of Bottom Paper | 400mm | |

| Height of Top Paper | 1800mm | |

* THIS CATALG FOR REFERENCE OLY, SPECIFICATION SUBJECTS CHANGE WITHOUT NOTICEFunctions of Flute Laminating machineThis Auto High-speed Flute Laminating machine is capable to laminate and glue combination of corrugated board and board together. After shearing or mold cutting, the laminated products can be made into carton box, advertising board and related products.

| Top sheet feeding section |

|

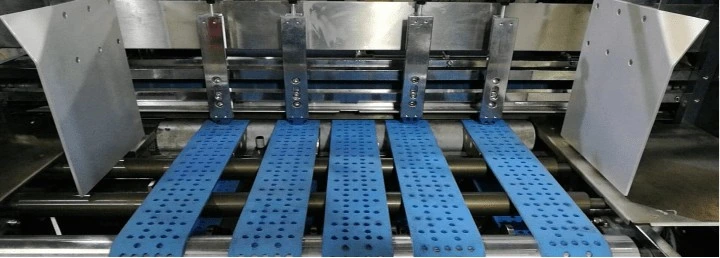

| Bottom sheet feeding section |

The lower suction belts driven by Yaskawa servo motor to assure accurate sheet feeding.n Pneumatic bar can press the front edge of boards for smooth feeding when the boards are curved

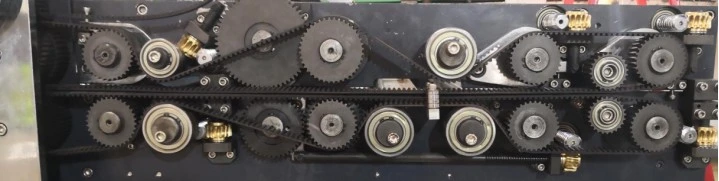

| Transmission System |

Power transmission evenly distributed by gears and belts combination, maintenance free, low noise, high efficiency.

|

| Gluing section |

High precise coating stainless steel roller mechanism assures even adhesive applied.Special mechanism ensures paper stripping off the gluing roller, easy to clean, dismantle and adjustThree sensors to control the glue volume level automatically.Side Glue stopper ensures no overflow at high speed and glue re-circulation at high speed.

|

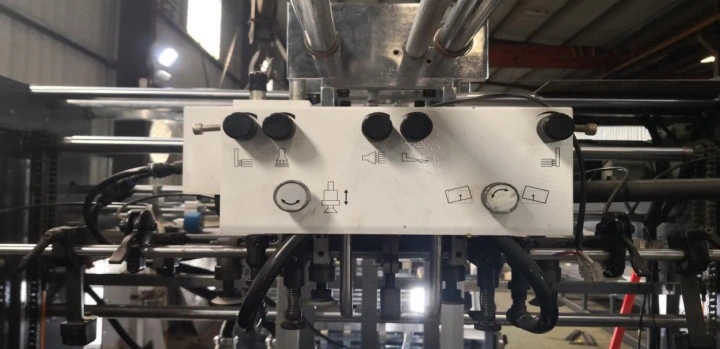

| Control Panel |

|

| Machine components |

| Components | Brand | Origin |

| PLC | Delta | Taiwan |

| Touch screen | Delta | Taiwan |

| Servo motor | Delta / Schneider | Taiwan |

| Frequency converter | Delta | Taiwan |

| Air pump | Becker | German |

| Motor | Simens | German |

| Air switch | Schneider | France |

| Button / Switch | MOELLER | German |

| Photoelectric sensor | Omron | Japan |

| Contactor | Schneider | German |

| Relay | Omron | Japan |

| Encoder | Autonics | Korea |

| Reducer | Liming | Taiwan |

| High frequency valve | SMC | |

| Bearing | NSK | Japan |

| Timing belt | GATES | USA |

| Conveyor belt | Nitta | Japan |

You may also like

Send inquiry

Send now