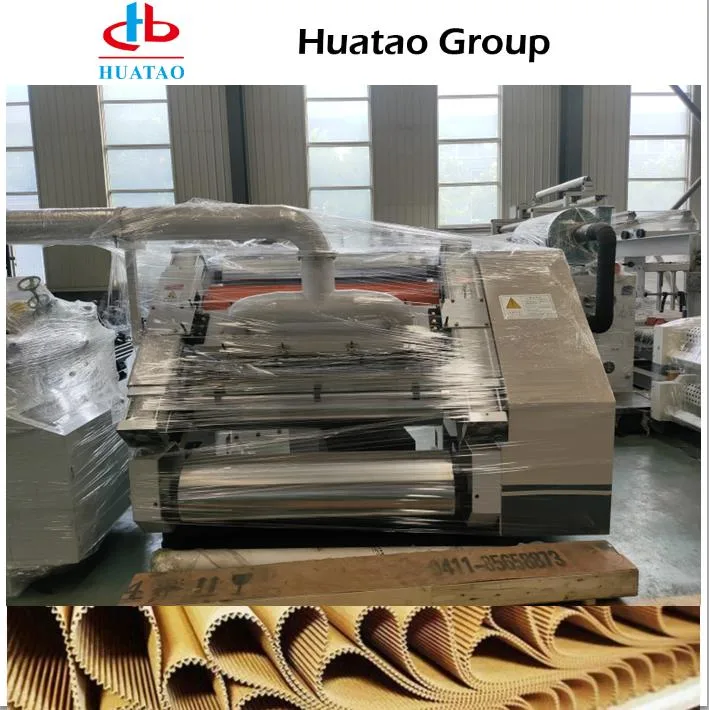

Automatic Cassette Roller Single Facer with Different Flute Design

Basic Info

| Model NO. | HT |

| Corrugating Roll Type | Tungsten Carbide /Hard Chrome Type |

| Type in Corrugated Cardboard | 3/5/7 Ply |

| Special Requirement | Can Be Customized |

| Production Time | 2 Months |

| Technical Support | Yes,Engineer Can Be Visit Plant |

| Mill Roll Stand | Hydraulic Shaftless/Electrical Shaftless |

| Visit Plant | Welcome Any Time |

| Transport Package | Plastic Film Wooden Case |

| Specification | 1600-2500mm width |

| Trademark | HUATAO |

| Origin | China |

| HS Code | 8401200000 |

| Production Capacity | 10 Sets/Month |

Product Description

Product Description

*Single facer is design for producing single-face corrugated paper:This machine is cassette type design, easy and quick to change flute in 15mins with dolly by hydraulic system

* Cardboard transmitting method adopts wind absorption, and keep flute profiles stable under the running condition of high speed.

* The wind machine absorbs corrugated paper to corrugated rollers through vacuum box and form corrugated profile.

* The width of wind groove of lower roller is not exceeding 2.5mm,and will less fringe marks of single corrugated paperboard.

* Transmission part adopt gimbal transmission, away from vibration source, and make the transmission more steady and reliable, and easy to maintain.

* The speed reducing box is oil-lubricating, close gear transmission, and will reduce machine vibration.

* Glue unit adopts auto-supply glue circularly, pneumatically reset and has buffering effect.

* Glue area will be electrically adjusted, glue unit can be running independently when machine steppes, and prevent glue running out.

* Upper corrugated roller surface are treated by special mesh snicked and chrome plated.

* Glue unit independent drive, pump-draw style, easy maintain and clean.

* Corrugated forming unit is designed with small independent wall plate. The roller is easy to disassembly, maintain, and quickly change flute profiles.

* Upper-lower corrugated rollers are made of high quality 48CrMo alloy steel, and after heat-treatment, the rigidity is HRC 56-60, surface do tungsten carbide treatment

Detailed Photos

Product Parameters

| Design Speed m/min | Running Speed m/min | Working width | Multy Ply Board |

| 100 | 60-80 | 1400-2000 | 3/5ply |

| 150 | 80-120 | 1400-2500 | 3/5/7 ply |

| 200 | 120-180 | 1400-2500 | 3/5/7 ply |

| 300 | 150-250 | 1400-2500 | 3/5/7 ply |

Packaging & Shipping

Our Advantages

1. Your inquiry related to our product & price will be replied within 24 hours.

2. Rich experience in packaging mechinery parts.

3. Bulk purchase quantities

4. Share the competitive prices with customer.

5. Good quality control and after-saled support.

6. Guaranteed delivery time.