300PCS/Min Corrugated Cardboard Paperboard Carton Box Flexo Automatic Feeding Printer Rotary Slotter and Die Cutter

Basic Info

| Structure | Unit Type |

| Application | Pre Printed Carton |

| Automatic Grade | Automatic |

| Printing Speed | 250-350 |

| Transport Package | Wooden Box |

| Trademark | Haiyang |

| Origin | China |

| HS Code | 8401309000 |

| Production Capacity | 100set/Month |

Product Description

High Speed Carton Flexo Printing Machine with Slotting Die Cutting Folder Gluer StitcherProduct DescriptionProduct Application

| Design Speed | 150pcs/min | 150pcs/min | 150pcs/min |

| Economy Speed | 120pcs/min | 120pcs/min | 120pcs/min |

| Max.Paper Sizes | 900x1800/2000/2200/2400/2600mm | 1200x1800/2000/2200/2400/2600mm | 1400x1800/2000/2200/2400/2600mm |

| Min.Paper SizePositive knifeNegative knife | 300x640mm300x720mm | 350x720mm350x740mm | 400x720mm400x740mm |

| Max.Printing Size | 900x1600/1800/2000/2200/2400 | 1200x1600/1800/2000/2200/2400/ | 1400x1600/1800/2000/2200/2400/ |

| Max die-cutting size | 900x1750/1950/2150/2350/2550 | 1200x1750/1950/2150/2350/2550 | 1400x1750/1950/2150/2350/2550 |

| Standard Printing Plate Thickness | 7.2mm | 7.2mm | 7.2mm |

| Slot Width X Max.Depth | 7x220mm | 7x300mm | 7x350mm |

| Min.Slot SpacePositive knifeNegative knife | 150*150*150*150250*90*250*90 | 170*170*170*170250*90*250*90 | 170*170*170*170250*90*250*90 |

| Printing roller dia(plus printing plate thickness) | 300mm | 408mm | 480mm |

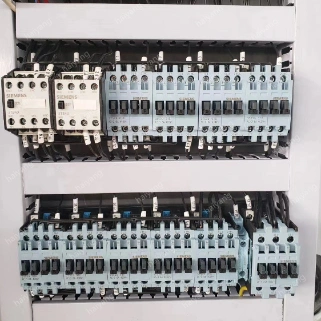

Main Features1) The whole machine is adopted international famous brand appliances SIEMENS, SCHNEIDER,the quality is reliable.2) The machine drive bearing,important driving parts adopt three major domestic famous brand "Hava los,long service lifer.3) The main motor is adopted frequency conversion control.It makes start,running more steadily and save more energy.4) Printer unit has Printing mounting function,fast printing speed.

Detailed Images

The whole machine is adopted international famous brand and computer software,such as SIEMENS,DELTA,OMRON, The quality is stable and realize. | |

| 1.The Electrical components are used internationally famous brands.Mainly control is adopted US servo numerical control positioning technology.Feeding unit,printing unit, slotting unit,die cutting unit are equipped with colorful PLC touch screen, with one touch machining setting with zero function can be connected to ERP system 2.The machine with order memory,easy to change the order 3.With ink shortage alarm to avoid the wastage. 4.In particular with computer remote maintenance;more easier to resolve equipment failure, more efficiency and reduce the cost maintenance | |

| The pressure of 3ply 5ply 7ply is setting by our patent high precision minor pressure adjustment,which work in with PLC and the accuracy is +- 0.01. |

Charactteristics

1.Four shaft lead edge vacuum transfer feeding system,the pressure of suction is adopted frequency control,which can apply for difference size and bending of cardboard.

2.The main drive system is adopted US EMERSON servo control.It can make more accuracy and improve the service life of the machine

3.It is using precise screw with linear guide , which is prevent the cutting holder locked with cutting shaft and make it more accuracy.

4.Die cutting rubber roller is adopted Emerson servo drive with mechanical speed compensation.

5.With No-key connection ring.There will be no clearance after long time using., so that it has high precision for positioning and exact overprint.

6.The transmission gear is made of high quality alloy steel, which is processed by tungsten carbide and treated by heat treatment and Rockwell hardness of 58-62 degrees.

7.With doctor blade interchange rubber roller structure;Change the mechanical configuration more flexible.

8.Paper feeding wheel adopts rack type with quick adjusting structure without wrench.

Factory

Packing & Delivery